High-Performance Drives

Our high performance drives offer exceptional power density, high efficiency, superior accuracy and are designed to be used in harsh environments.

-

-

Calculation and Optimization of Magnetic Circuits

-

-

Our customer specific brushless DC motors are designed by means of Finite Element Analysis. Thereby, we can optimize the geometry and verify different properties, as magnets, iron and windings Highest levels of rotational consistency due to groove-free design

- High speed (200,000 rpm) / Low speed (50,000 rpm)

- No torque ripple due to slotless design

- Sensor-based / sensorless motor control

-

-

-

-

Development of Power Electronics for Drives

-

-

Decades of experience in electronics development combined with expertise in drives are the key factors in our 35-year ongoing success story. Our interdisciplinary team allows a close interaction of hardware and software at the microcontroller level is particularly important for development of high-end applications.

-

-

-

-

Production of Special Tools

-

-

Together with our long-time partners, we have built up extensive expertise in the design and production of special tools. This enables us to respond quickly and efficiently to specific customer requirements.

-

-

-

-

Prototyping/Prototype Production

-

-

Throughout various design phases of a development project, our customers value our in-house prototyping and prototyping capabilities. Our rapid response times support efficient project execution and cope with tight schedules.

-

-

-

-

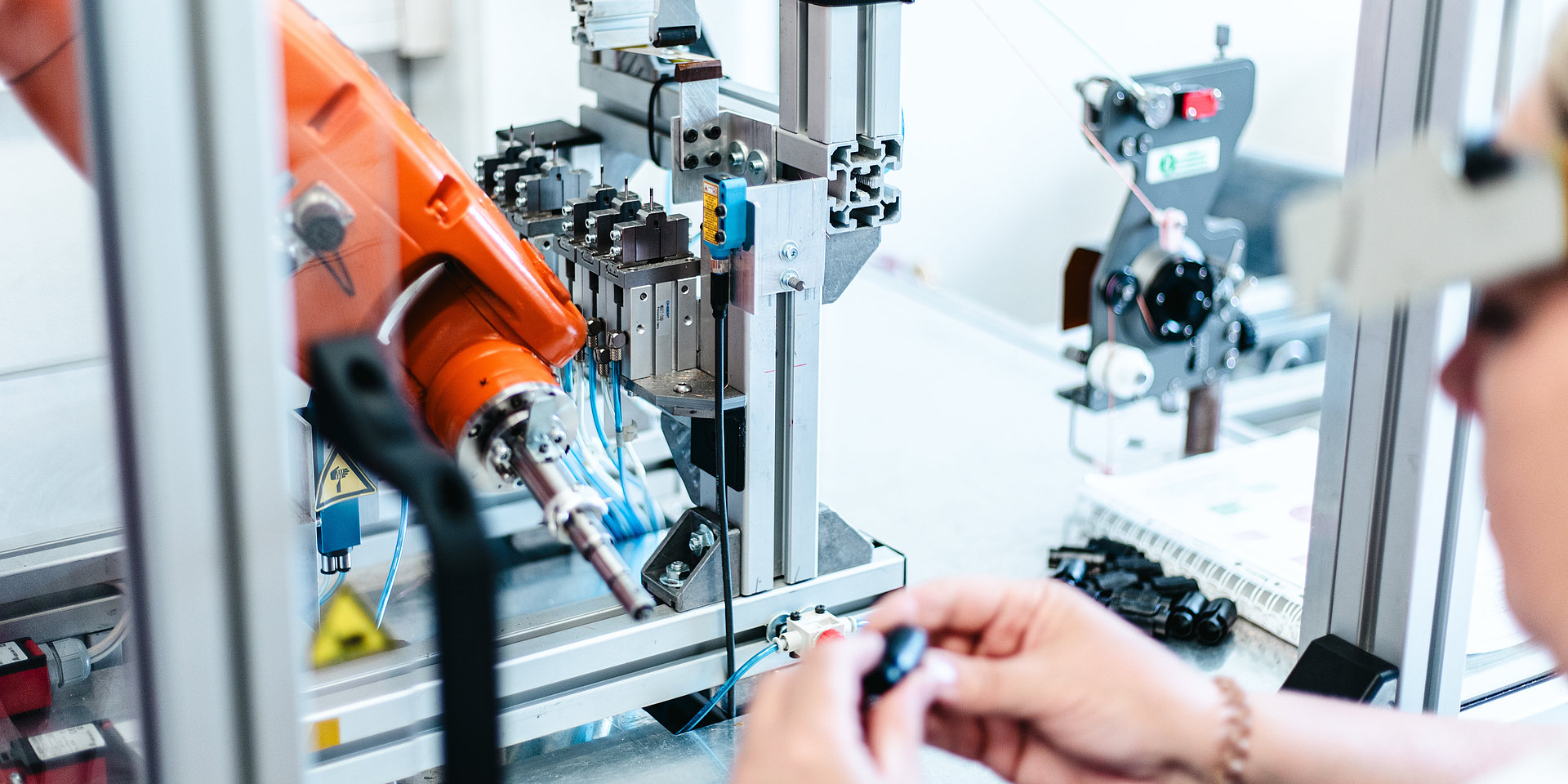

Production Process Development

-

-

Due to our high-mix / low-volume product portfolio with hand-made goods, efficient manufacturing processes are crucial for the production of miniaturized high-performance drives.

-

-

-

-

Stator Production

-

-

We provide small series with hand-made stator windings as well as medium-sized series with partially automated processes:

- Coil production

- Sheet metal processing

- Laser- welded lamination stacks

- Assembly of windings to stator coil

- Integration of motor controls and bearing seats

- Molding and encapsulation of stators

- Quality control during the process

-

-

-

-

Testing

-

-

We provide custom test benches in order to perform specific measurements on our drives. Enabling us to record various parameters such as geometry and electrical quantities:

- Run-in (reliability testing)

- Climate chamber

- Steam sterilization (autoclave)

-

-

-

-

Logistics

-

-

Labeling and packaging are crucial elements of effective logistics. Accurate labeling enables clear identification of goods and optimizes part management. Proper packaging protects products during transportation and minimizes damage. We only ship to our end customers after careful preparation.

-

-

-

-

Quality

-

-

The base of long-term customer satisfaction is compliance with EN ISO 9001 and EN ISO 13485 for quality management. Compliance to international guidelines ensures global conformity with the highest standards.

-

-

-

-

“For almost 10 years, we have seen Ottronic as a responsive and innovative partner for our high-tech products. The close cooperation in product development and production creates a classic win-win situation for both parties.”

Ingo Häusl, CEO at HP-Tech

-

Contact

Ottronic Regeltechnik Gesellschaft m.b.H.

Ankerweg 1

8753 Fohnsdorf

Austria